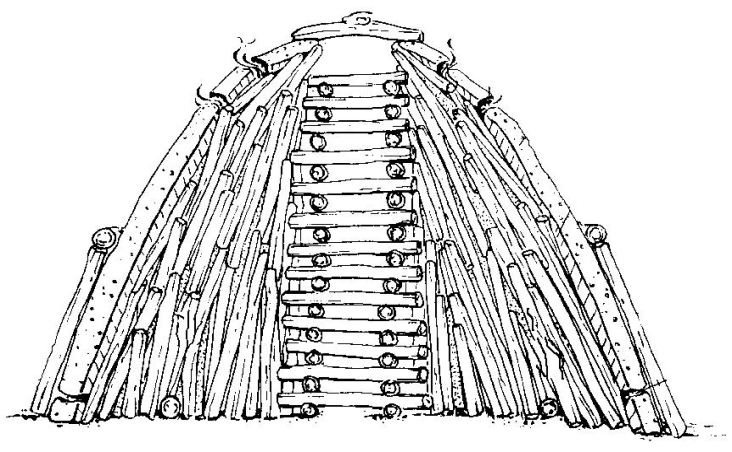

Schematic construction of a charcoal kiln

The kiln 'burns' between 6 and 20 days

From 500 BC (La Tene period) until the mid-19th century charcoal was the only fuel for the wind furnaces and the blast furnaces in this area. The oldest method for gaining charcoal is the charcoal pile. Ever since ancient times the method has stayed the same: Wood logs are vertically piled up in a cone-shaped pile and then covered with earth and sods. Under this surfacing the burning is started. Air supply is regulated and controlled so that the wood does not burst into flames, and the temperature is kept at 300-400 degrees Celsius, the perfect charring temperature. So they get about 30-35% charcoal out of the original amount of wood. Charcoal burns with a higher temperature than wood. For the production of 1 kg iron more than 125 kg wood was necessary and thus the woods diminished especially in places with lots of smelting furnaces. In the valleys surrounding the Eisernhardt there were numerous sites for charcoal piles. In the late Middle Ages a blast furnace was about 5-8 m high and 3 m in diameter, provided with blowers for higher temperature. But they needed tons of charcoal – the consequence was a permanent scarcity of wood in the forests. To stop plundering the local woods a woodand-forest-ordering-decree (Siegerländer Haubergsordnung) was enacted in 1562 by Earl Johann of Nassau to regulate the use of woods as energy supply. In 1444, there were 29 iron and steel works in Siegerland which needed 90,000 cubic metres of wood. In the late 18th century Siegerland iron industry needed 10,000-12,000 lorry loads of charcoal every year, about one third of the amount came from Siegerland itself and the rest (6,000-8,000 lorry loads; 1 lorry approx. 1.4 tons) from neighbouring areas. It wasn’t until 1860 that blast furnaces were fired with glance coal. Glance coal from the Ruhr area could then be transported to this region, due to the new railroad network.